New Smart Factory Construction (Basic MES)

Transforming the factory into a smart facility to achieve manufacturing innovation.1 Raw Material Receiving/Incoming Inspection

Management System

by QR Code

• Inventory payment support

• Returns, Sorting Process, and Cost Handling

-

Raw Material Receiving

PBT, SHIELD RING,

COLLAR, UNIT SEAL -

Import Inspection

Notification of Defective History to Supplier (Returns), Incoming Inspection Log/ Certificate

-

Raw material drying/inspection

ROPPER,

Moisture Measurement Test

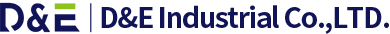

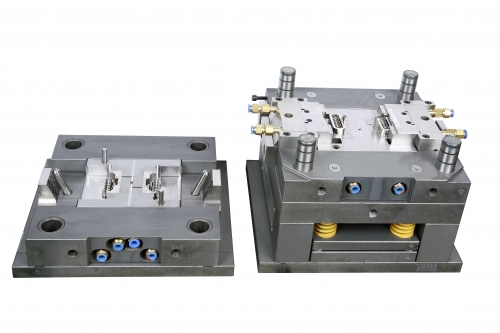

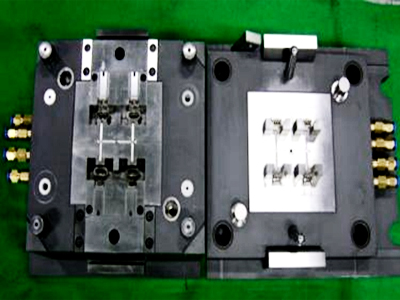

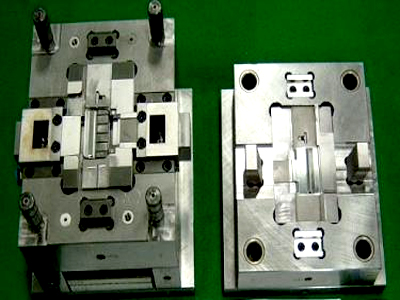

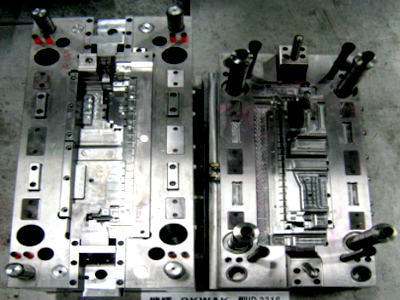

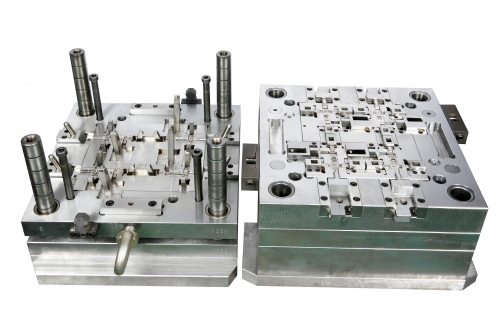

2 [Injection Molding] Mass Production / Process Inspection

• Completion Processing by QR for Each Process

• Process Status Monitoring

-

[Injection] Machine Settings

Pressure (kg⋅m), velocity (m/sec), position (mm), time (sec), etc.

-

[Injection] Mass Production

40,000 pieces per day (LOT) production with 10 facilities

-

[Injection] Process Inspection

Dimension (V/C, Coordinate Measuring Machine), Appearance (Visual Inspection), Early・mid・and final work

3 Assembly process/

appearance inspection

the aggregation of

production performance.

• Share work information issues

• ROT Tray Packaging

-

Packaging(TRAY)

Qty(42EA)*7Pcs 294EA P-BOX : LOT

-

Pre-assembly visual inspection

Free of functionally harmful blemishes, rust, scratches, deformities, discoloration, etc.

-

Assembly Process

SHIELD RING, COLLAR, LINIT SEAL Standard of Practice

4 Final product

quality inspection

pass/fail processing

• Quality Status Report

• Preparation of defect report.

-

ASS'Y Visual Inspection

SHIELD RING, COLLAR, etc.

-

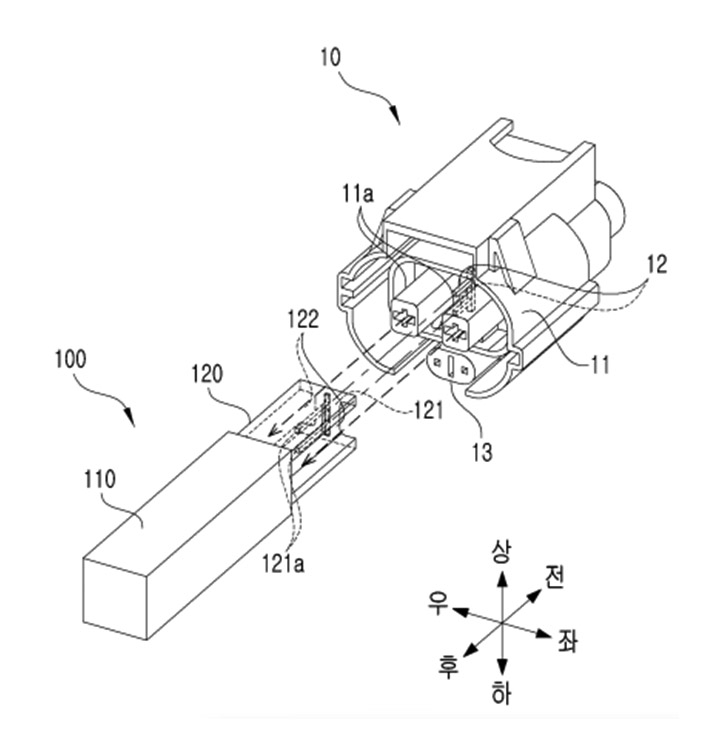

Vision Inspection

Vision inspector internal camera

-

ASS'Y Final Inspection

Finished Goods Visual Inspection Standard

5 Packaging/Shipping

shipping history

• Issue a bill of sale

• LOT history traceability available

-

Packaging

Use of standard BOX

-

Shipping

Shipping LOT Management